Interpreting large volumes of real-time and historical data

Turning Environmental Monitoring into Operational Confidence

Background & Context

Across industries, maintaining precise environmental conditions is not a convenience—it is a requirement.

Businesses dealing with refrigerated or frozen goods, food preparation firms tracking shelf life, hospitals storing vaccines, and enterprises operating temperature-sensitive equipment all depend on accurate, continuous monitoring. In parallel, government bodies and food safety inspectors increasingly require access to this data to ensure compliance with health and safety regulations.

At the center of these operations are IoT-enabled sensors that continuously track temperature, humidity, power usage, and device performance. These sensors feed data into open IoT platforms that function well as data collectors, but fall short when it comes to interpretation, usability, and decision-making.

This is where our client saw an opportunity.

The Challenge

While sensor data was being captured reliably, organizations struggled with:

Responding quickly to temperature breaches, power loss, or device malfunction

Monitoring multiple locations, units, and devices efficiently

Reducing costs caused by manual data logging and delayed intervention

Meeting compliance and audit requirements with confidence

Providing accessible insights to partners and end users

Existing platforms worked well as technical backends, but not as operational tools.

The client wanted to create a solution that would sit above the IoT layer, consume sensor data, and convert it into clear, actionable intelligence-usable across industries and scalable through partner channels.

The Objective

To build a cloud-based IoT ecosystem that would:

Enable real-time and historical monitoring of equipment

Support compliance with food safety and health regulations

Deliver alerts before failures lead to losses

Provide role-based access for partners and end customers

Work seamlessly across web and mobile devices

Eliminate manual record keeping and fragmented reporting

Our Approach

We focused on data comprehension, accessibility, and actionability.

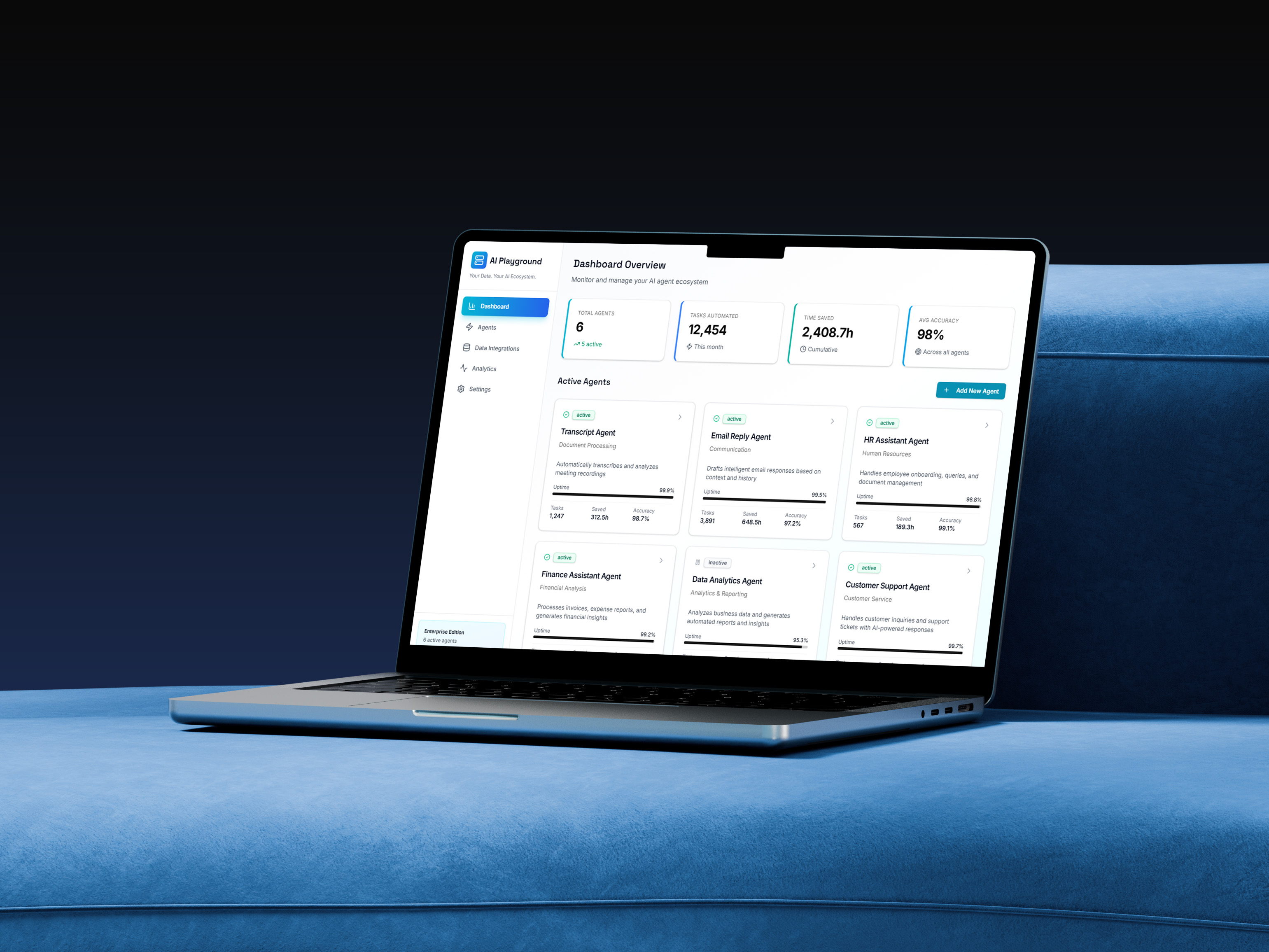

Instead of reinventing sensor hardware, we designed a custom intelligence layer that integrates with existing IoT data sources and transforms raw readings into meaningful insights.

The Solution

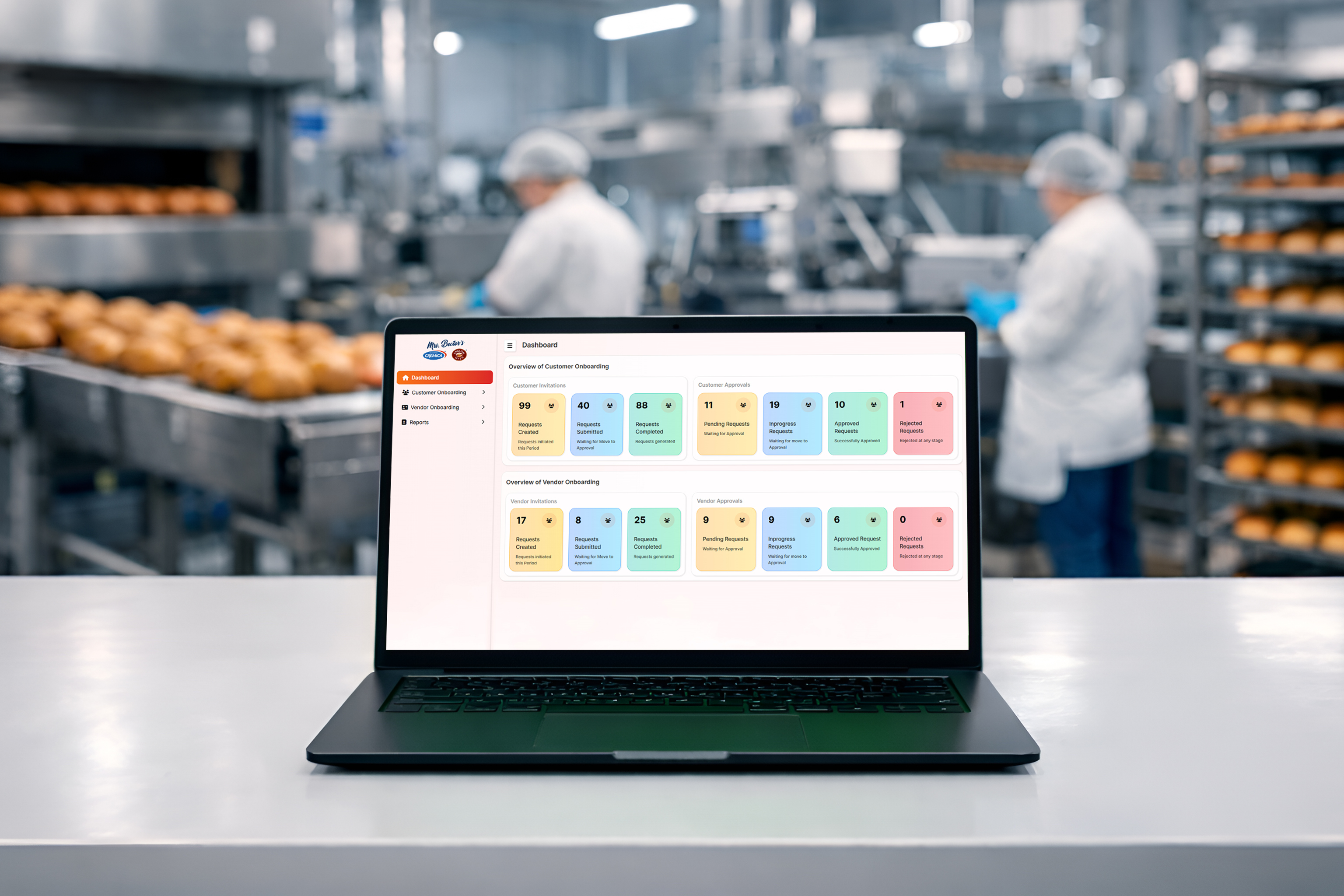

We developed a cloud-based IoT monitoring and analytics platform that continuously gathers real-time data from connected devices and presents it through an intuitive, easy-to-use interface.

The platform enables users to monitor equipment health, track performance historically, and respond instantly to anomalies—before they turn into costly failures.

Core Capabilities

Real-Time Monitoring & Alerts

Continuous tracking of temperature, humidity, and power usage

Instant alerts when values breach defined thresholds

Early warnings for equipment malfunction or power loss

Historical Performance Analysis

Day-wise and sensor-wise data visualization

Ability to look back at equipment performance over time

Better planning for maintenance and replacements

Power Consumption Tracking

Monitoring electricity usage for 110v–220v AC equipment

Identifying inefficient devices

Reducing energy costs and preventing breakdowns

On-Demand Reporting

Easy generation of digital reports for audits and inspections

Data accessible with a few clicks—no manual paperwork

Secure cloud storage for long-term record keeping

Multi-Unit & Multi-User Access

Centralized monitoring of multiple locations and devices

Designed for both end customers and partner channels

Role-based access without operational complexity

Cloud-First Architecture

No additional investment in servers or system maintenance

Secure data storage managed entirely in the cloud

Scalable foundation for future expansion

Industry Use Cases

The platform was designed to be sector-agnostic, enabling rapid adaptation across industries.

Food Service & Cold Chain

Meet HACCP standards

Prevent spoilage and ensure food safety

Maintain temperature and humidity compliance

Vaccines & Medical Supplies

Preserve vaccine and medicine effectiveness

Monitor refrigeration units continuously

Receive early alerts for power loss or abnormal consumption

Facility Management

Remotely manage office equipment

Ensure appliances are turned off after hours

Reduce energy waste and carbon footprint

Vending Machine Monitoring

Optimize operating schedules

Track electricity usage

Enable preventive maintenance and reduce CO₂ emissions

The Impact

The platform shifted organizations from manual, reactive monitoring to automated, proactive control.

Operational Benefits

Faster response to temperature and equipment anomalies

Reduced product deterioration and financial loss

Improved compliance with regulatory requirements

User Experience

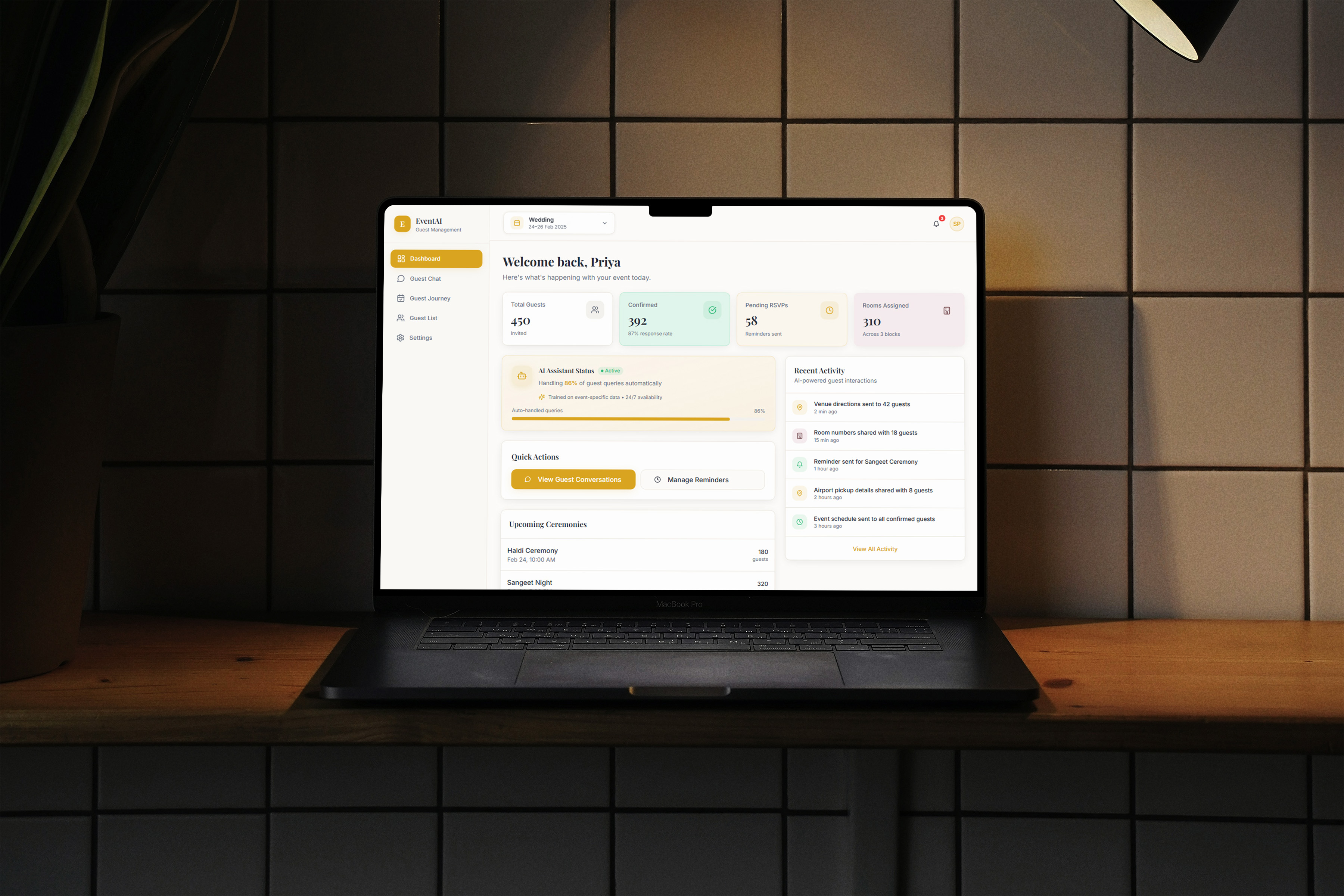

Access to insights via PC, tablet, or smartphone

Clear dashboards instead of technical data dumps

Confidence in decision-making backed by real data

Business Benefits

Lower operational and energy costs

Elimination of manual data collection

Scalable deployment through partner networks

The Challenge

This project demonstrates how cloud-based IoT intelligence, when designed with usability and compliance in mind, can unlock real value across industries.

By transforming sensor data into clear insights, timely alerts, and actionable reports, we helped the client build a platform that supports daily operations, regulatory compliance, and long-term efficiency—without adding technical burden to the user

Testimonials from our valued clients

We bring our experience, expertise, and innovative mindset into every project to deliver the best results.

Tech Stack

Node.js

Angular

Postgres

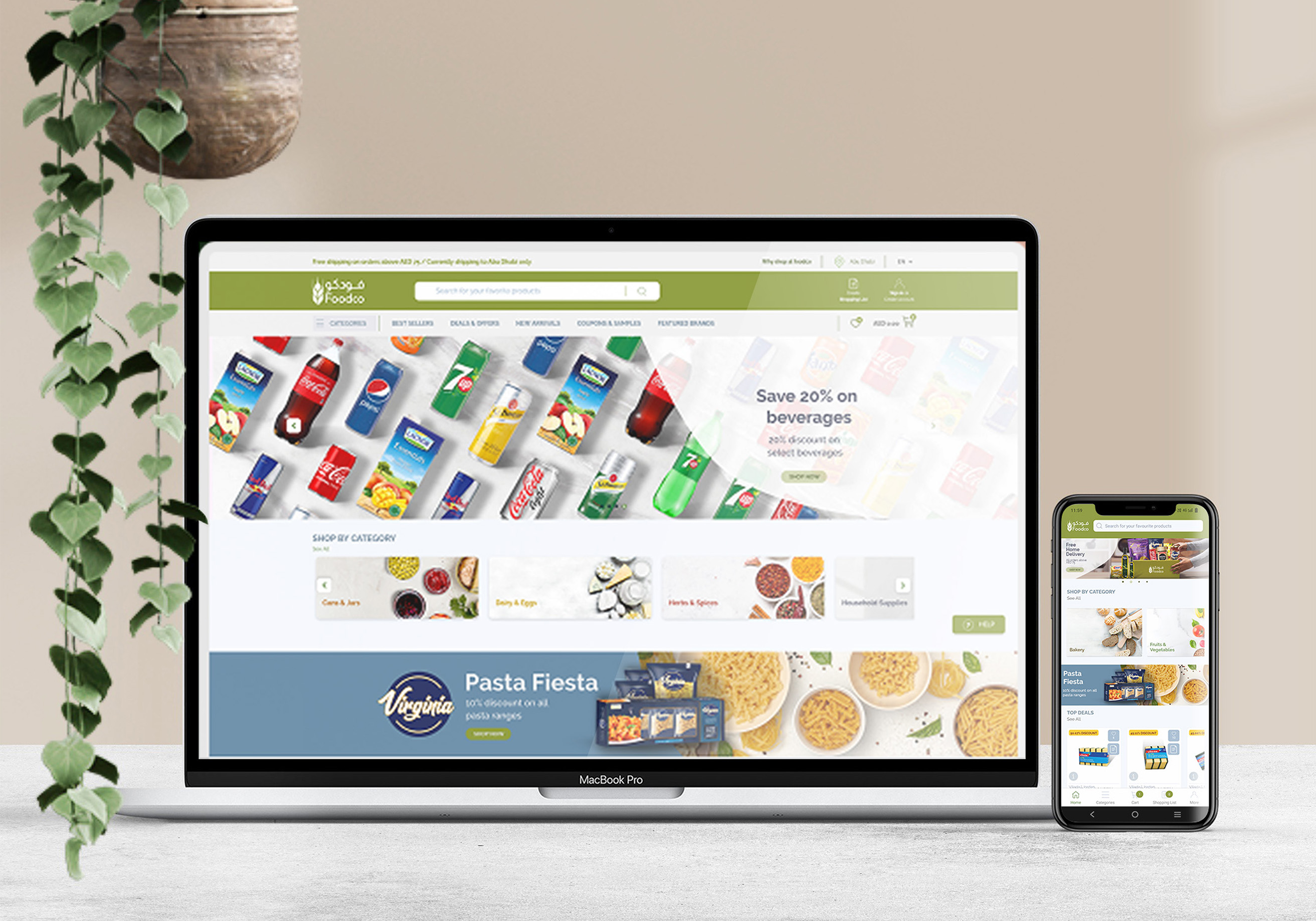

More Case Studies

Case Study

Solutions for Every Industry and Vertical Built with Expertise

We rely on the industry’s best practices, growth strategies, and customer behavior to build relevant and performant solutions.